Product Overview

At present, the steel cord conveyor belt has been widely used in mines, ports, cement plants and other fields, the steel cord conveyor belt has the advantages of long conveying distance, large volume, continuous transportation, and reliable operation, easy to automate and centralized control, Especially for high-yield and high-efficiency enterprises, the steel cord conveyor belt has become one of the major transmission equipment in modern production at home and abroad.

Steel cord conveyor belt in the operation of the joint twitch occurs or the internal wire rope breakage, ranging from the conveyor belt caused by the slide, the conveyor belt damaged, heavy cause casualties. Therefore, how to achieve the safety of steel cord conveyor belt transport priority.

KJ898 mining steel cord conveyor belt magnetic testing system developed by our company can accurately detect the twitching and displacement of the steel cord joint in the conveyor belt by the fifth generation of machine technology and accurately identify the broken cord, fatigue and rust. Completely eliminate hidden dangers of accidents. In addition, on the basis of the fourth generation of products, this system adopts the principle of double-loop time difference magnetic balance to effectively overcome the influence of belt jitter and deviation on test results. In order to make the test results intuitive and easy to understand, the fifth generation of products adopts the latest simulation technology. The software testing interface accurately restores the shape of the steel wire rope inside the conveyor belt. It is as clear as scanning the conveyor belt for X-ray scanning and decapitation.

Product Functions

KEWEI is committed to continuously exceed and innovate, in addition to the following products have the following basic functions, but also based on and customer requirements to achieve more personalized features.

1 Online monitoring, accurate positioning:

This system achieve really online monitoring and accurate positioning for the steel wire rope embedded in the conveyor,such as deformation, wear and tear. Corrosion, loose stock, jumping wire and other defects of the type.

2 Audible alarm:

Manually set alarm threshold,When joint twitch or broken wires stocks to set threshold, the software of automatic alarm.

3 Display:

PC software provides two kinds of display mode,being user mode and precision analysis,The user mode adopts simulation technology and show the actual state of wire rope in the conveyor belt.Precision analysis is used to accurately analyze specific injury.

4 Data storage and Test report generation:

The software automatically stores test data and automatically generate daily, monthly and annual reports,historical data can be preserved for more than 5 years.

5 Data sharing:

The test data can be uploaded to the Internet,users can know the safe state of the conveyor belt at any time.

6 one loading more form:

A main engine detects multiple conveyor belts and manually switch automatically.

7 Prevents the deflection of the conveyor belt:

The sensor box is slightly wider than the belt to avoid missing when preventing the deflection .

8 Overcome the problem of jitter:

This product uses the patented "magnetic balance" detection technology,to conquer the impactof jitter on accuracy of detection.

9 Data will look, photo comparison:

Realize historical data review, take pictures, contrast function, changes in wire rope operating conditions more intuitive.

10 Quick positioning of the joint and Co-Browsing:

The connection number of the computer display is consistent with the actual joint number,new connections can be customized by the user,it is convenient for users to quickly locate the joint.

11 Remote control power:

The system is automatically powered up when you open the monitoring software to begin the detection;The conveyor belt stops running,the system will automatically cut off power,meanwhile achieve automatic detection and unattended operation.

12 Remote technical support:

The detection data can be sent to the supplier by Internet ,thus the customer can get technical support from our experts.

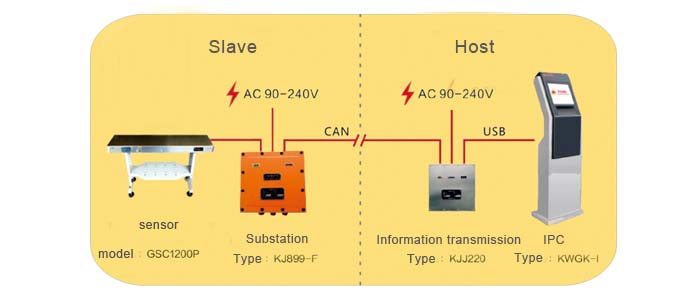

System Composition

The system is composed of intrinsic safety type magnetic digital sensor、the industrial control computer、intrinsic safety type transmission interface 、substation and other relevant equipments.

1 Sensor :Integrating Non-Contact Speed Sensor and single chip microcomputer,

the sensor detects the flaw of the wirerope and transforms it into an analog signal .The single chip microcomputer achieves the conversion from analog to digital and the signal processing ,then transforms the useful signal into the CAN bus signal .

2 Substation: (type of protection :flameproof enclosure & intrinsic safety )

Be composed of the Intrinsically Safe Power、the servo single chip microcomputer and the Data acquisition and communication module.The Intrinsically Safe Power(12V/2A) supplies power to sensors group and single chip microcomputer separately.According to host computer’s order , the servo single chip microcomputer opens and closes main supply power , or stops steel wire rope running.The Data acquisition and communication module mainly receives the signal from sensor groups , then processes and packages for transmitting to the host computer.

3 Transmission interface: As a safety barrier ,it is composed of the Intrinsically

Safe Power and the Communication data conversion interface.The former supplies power to the latter. Communication data conversion interface transforms the CAN

signal into the USB signal , which is transmited to computer.

4 Industrial computer stations on the host: from the special cabinets, industrial computers, special wire rope data processing software, printers, SMS notification module. Role for the collection and processing of data, display graphics, store data, analyze and determine the type of defect, generate test reports, print reports and text messages to inform customers.

Technology Improvement

1 Sensor improvements:

①improve the detection of small signal accuracy;

②improve the resolution of the signal;

③sensor output signal becomes smaller, to solve the problem of signal disconnection.

2 Microcontroller improvements:

Three 98 series MCU, 32-bit ARM microcontroller to completely solve the problem of asynchronous microcontroller to solve the display of the problem of dislocation, the judge to determine more twitching joints.

3 Lower machine increase servo microcontroller:

①to solve the upper computer control bit machine automatically powered and off the power to improve the sensor and the next crew of the service life;

②When the joint twitch and break more than 10%, automatically stop the tape running.

4 Interruption problem:

①SCM has been collecting signals to solve the problem of missing signals caused by interruptio;

②plower machine filter signal, too big and too small signal to be filtered.

5 A drag more machine problems:

Solve the problem of automatic switching, truly a communication cable control multiple devices.

6 Improve screen simulation of real wire rope problems:

①broken wire and broken wire directly into a wire rope broken wire and broken rope state;

②connector at the same time two ways to display: signal mode and wire rope way.

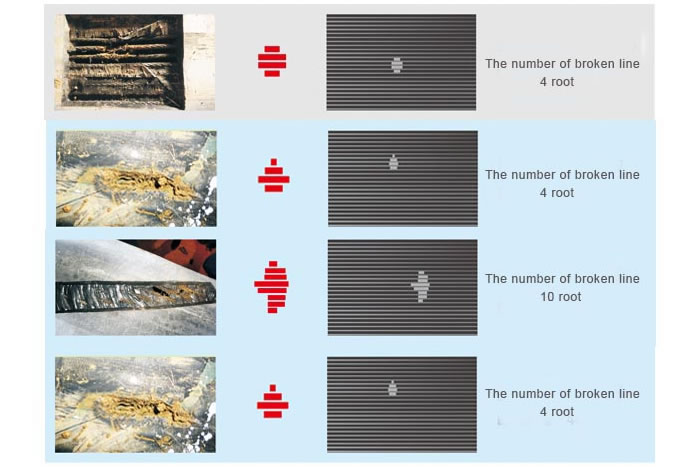

Measurement Graph Description

Applications

| 上一个:YSC60 | |

| 下一个:ZTD127/1.4 |

SHANXI KEWEI INDUCTIVE

CONTROL CO.,LTD

Add:DongMin Technology Building,

Taiyuan University of

Technology, Shanxi

Tel:86 351 3292666

Fax:86 351 6580268

E-mail:sxkwgk@126.com

Home | About Us | Product | Our Service | Contact us

Tel:86 351 3292666 E-mail:sxkwgk@126.com Add:DongMin Technology Building, Taiyuan University of Technology, Shanxi

Copyright: SHANXI KEWEI INDUCTIVE CONTROL CO.,LTD Technical support:Taiyuan University of Technology