|

evator wire rope, wire rope construction elevator, oil drilling rig. The main wire rope broken, wear or deformation and other loss signal acquisition and processing storage. After the completion of the test, the computer exported the wire rope injury data. Is the most advanced mine portable rope magnetic testing equipment.

The battery-powered products, the appearance of small, simple, safe and reliable, suitable for single-person portable measurement. Suitable for mine is not suitable for the installation of the computer scene. Easy to carry, affordable.

Main Functions

1 Real-time detection:

This product uses the patented "magnetic balance" detection technology to realize the comprehensive safety monitoring of the steel overhead traveling rocket device. Real-time online monitoring of defects such as broken wires, rust, abrasion, elasticity reduction.

2 Dynamic display:

The host computer reads the wire rope testing data from the wire rope testing sensor memory card and dynamically displays the current wire rope injury status in the software interface.

3 parameter settings:

The parameters should be set according to the actual situation on site. Including the basic information settings, analysis parameters set up two parts.

4 Data calibration:

Due to different test site environment, in order to eliminate wire jitter or other interference to ensure the accuracy of testing, the software has data self-learning function, that is, data calibration./span>

5 Automatic judgment:

Acquisition and measurement of data analysis and calculation of automatic judgment, to determine the degree of rope damage.

6 Data review:

Determine the position of the defective or damaged wire rope and review the historical data.

7 Automatically generate test reports:

When the wire rope defects detected, the defect information is saved to the database to generate test reports to facilitate print output.

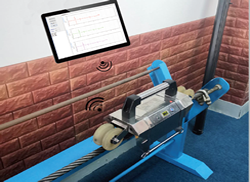

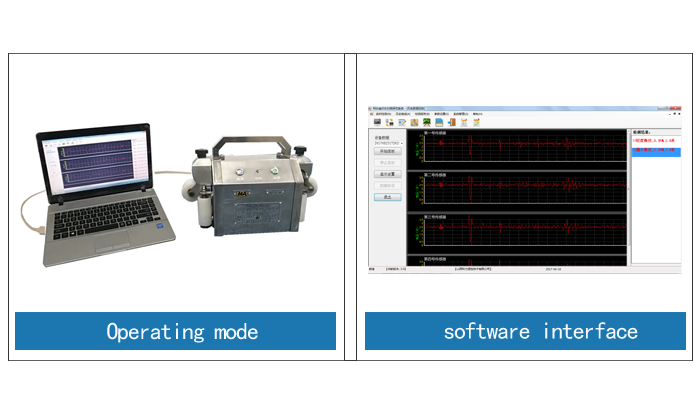

Operation Mode

According to the use of environmental requirements,the system has two kinds of work methods:on-line or off-line.

1 on-line:The harvester is connected directly to the computer and implementing online detection.After the test is completed, the test report will be generated.

2 off-line:The user can use the harvester separately to measure multiple wire ropes and complete data collection.After the collection, harvester connect with the computer,then analyze the data and generate test report.

Technical Specification

1 Detection rope diameter range:Φ10-32 mm Φ22-46 mm

2 Wire rope speed:1.0-20 m/s

3 Transmission speed:115200bps

4 Detection sensitivity:5V/GS

5 The distance between the sensor and the wire rope under test:10-50 mm

6 Broken wire detection sensitivity:≤0.5%

7 Continuous working time:24h

8 Working voltage:DC3.7V /4Ah

9 Working current:≤0.5A

10 Power:≤1.85w

11 Built-TF card capacity:8G

12 Communication method:RS232

13 Host weight:7kg

14 Enclosure rating:IP54

15 Ambient temperature:-20℃-55℃

16 Use of relative humidity:≤95%RH(25℃)

Test Cases

| 上一个:KWGD0X | |

| 下一个:KJ898 |

SHANXI KEWEI INDUCTIVE

CONTROL CO.,LTD

Add:DongMin Technology Building,

Taiyuan University of

Technology, Shanxi

Tel:86 351 3292666

Fax:86 351 6580268

E-mail:sxkwgk@126.com

Home | About Us | Product | Our Service | Contact us

Tel:86 351 3292666 E-mail:sxkwgk@126.com Add:DongMin Technology Building, Taiyuan University of Technology, Shanxi

Copyright: SHANXI KEWEI INDUCTIVE CONTROL CO.,LTD Technical support:Taiyuan University of Technology