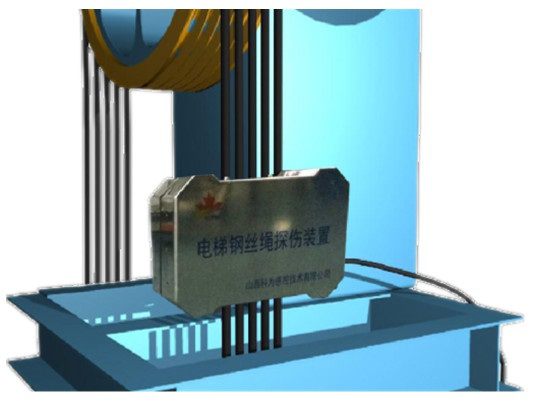

Product overview

The device is used in the elevator rope damage occurred during the process, such as broken wire, fatigue, corrosion, wear, crush, distortion and so on, real-time monitoring and analysis, and the results uploaded to the monitoring center or related maintenance personnel. Wire rope safety hazards to a minimum, improve the safety performance of the elevator. My company will be advanced magnetic balance detection technology applied to the system, improve the detection accuracy and accuracy of the system.

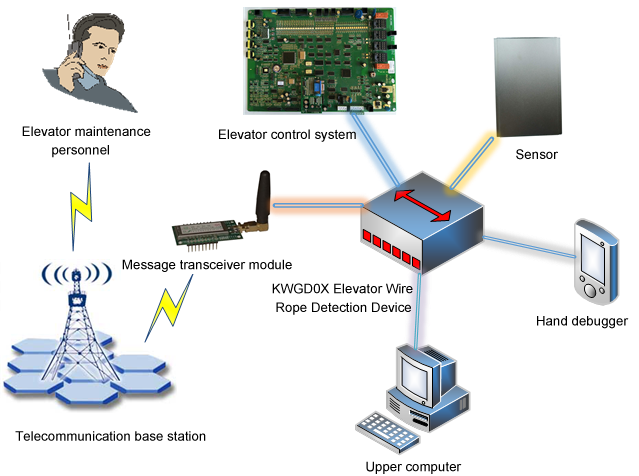

System Diagram

Functions

1 Online monitoring, accurate positioning.

2 Non-contact measurement.

3 Equipped with sophisticated speed sensor, with direction and positioning discrimination.

4 LED damage status indication, sensor status indication.

5 Remote SMS notification. (Optional)

6 Handheld debugger to see the damage.

7 PC online real-time view of the waveform, data storage, data review, data processing, automatic generation of test reports.

8 Software self-test function.

9 The system and the elevator master are integrated into the elevator control system through the CAN bus, which facilitates the judgment of the elevator master.

10 Mode selection: The device according to the scene and user needs is divided into high school with low. Low with standard configuration only contains elevator wire rope detection device without hand-held debugger and host computer; equipped with elevator wire rope detection device and hand-held debugger; high with elevator wire rope detection device and hand-held debugger and host computer. Based on the above configuration can also increase the SMS notification options.

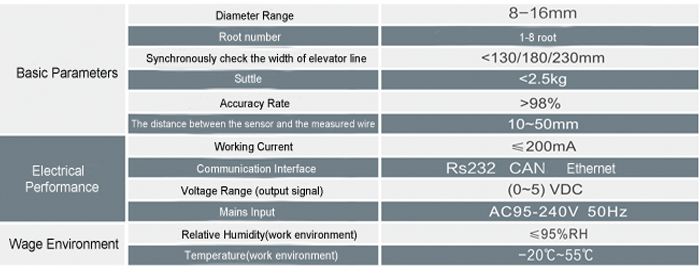

Technical Specification

Configuration Mode

1 Standard with the model: Does not include the hand-held debugger and the host computer, the system detects the wire rope has a broken wire signal through the sensor, the controller to determine the degree of injury, through the blue-green-red three-color LED instructions to determine the rope damage, including Blue indicates mild damage (3% broken or self-contained) Green indicates moderate damage (5% broken or self-contained) Red indicates heavy damage (12.5% broken or self-contained).

2 Medium with the model: In addition to the standard hand-held debugger, the user can not only through the three-color LED indicator to determine the damage of the wire rope, but also by hand-held debugger to observe the damage of each wire rope (including the degree, Location, rope speed, etc.).

3 High with the model: based on the increase in mode with PC real-time monitoring, the user can not only through the three-color LED indicator and handheld debugger to determine the damage of the wire rope, but also through the host computer real-time monitoring of each elevator rope injury Loss of waveform and its size, and to determine the level of injury intelligence, waveform data storage, data playback, automatic generation of reports and other functions.

4 In addition to the above three configurations, the system and the elevator master are integrated into the elevator control system via the CAN bus to facilitate the operation of the elevator master. This function can be used as an optional function.

5 SMS notification: The system regularly through the GSM network elevator rope damage to the user by SMS or security personnel to facilitate maintenance staff to keep abreast of the status of the elevator rope and take relevant measures.

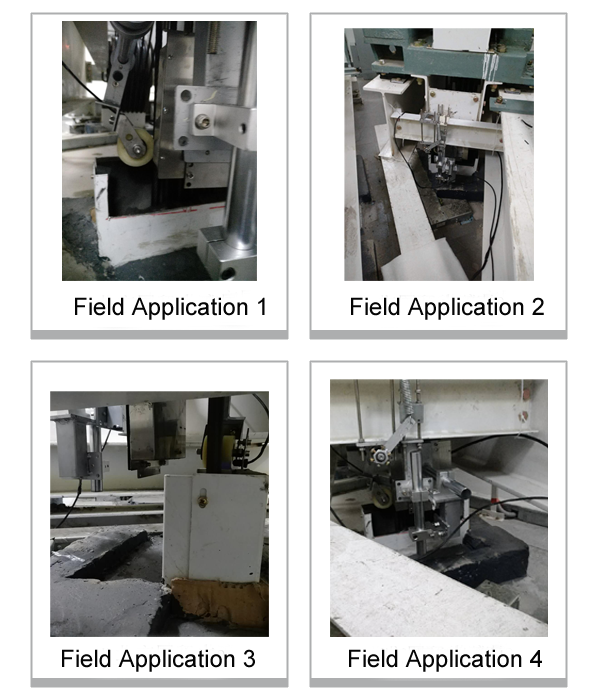

Applications

| 上一个:Kj965 | |

| 下一个:YSC60 |

SHANXI KEWEI INDUCTIVE

CONTROL CO.,LTD

Add:DongMin Technology Building,

Taiyuan University of

Technology, Shanxi

Tel:86 351 3292666

Fax:86 351 6580268

E-mail:sxkwgk@126.com

Home | About Us | Product | Our Service | Contact us

Tel:86 351 3292666 E-mail:sxkwgk@126.com Add:DongMin Technology Building, Taiyuan University of Technology, Shanxi

Copyright: SHANXI KEWEI INDUCTIVE CONTROL CO.,LTD Technical support:Taiyuan University of Technology