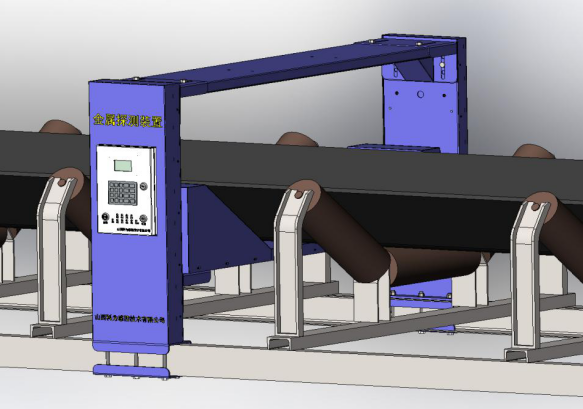

Product overview

This product is used for on-line detection of coal in coal conveyor coal flow and intelligent control of terminal equipment (such as iron removal) work to remove metal substances in order to achieve the purpose of conveyor protection, while intelligent terminal equipment, energy saving. The sensor adopts international advanced magnetic circuit balance principle, the host adopts advanced embedded digital system to realize data acquisition, data analysis, data display, alarm, control output, data remote transmission and other functions. By using this system can greatly increase the service life of iron separator, saving 80%.

Functions

1 Can detect the flow of iron in the coal, and determine the size and relative position.

2 Can intelligently control the stop and start of the separator in the final control equipment and save 80% of the energy consumption of the separator.

3 When the iron metal length is greater than the set value, the weight is greater than 50Kg (beyond the work of the separator range), can control the tape machine down or send remote alarm signal to the monitoring room, while the sound and light alarm, manual removal of ferrous metals, to avoid An accidental tear in the tape occurred.

4 When the device fails, the system will automatically open the iron separator, it has been maintained in working condition, to prevent the occurrence of ferrous metal missing tape longitudinal tear accident.

5 Can distinguish between iron metal and belt buckle, steel cord joints.

6 According to the actual needs of the user can set the lower limit detection of ferrous metals, iron metal is less than the lower limit to give up clearance.

7 This device can record the amount of iron removal in real time and the running time of the separator to make it easy for users to analyze the working conditions of the site.

8 The device can communicate through long-distance communication with the back-office network of the control center to facilitate real-time monitoring, data record analysis and preservation.

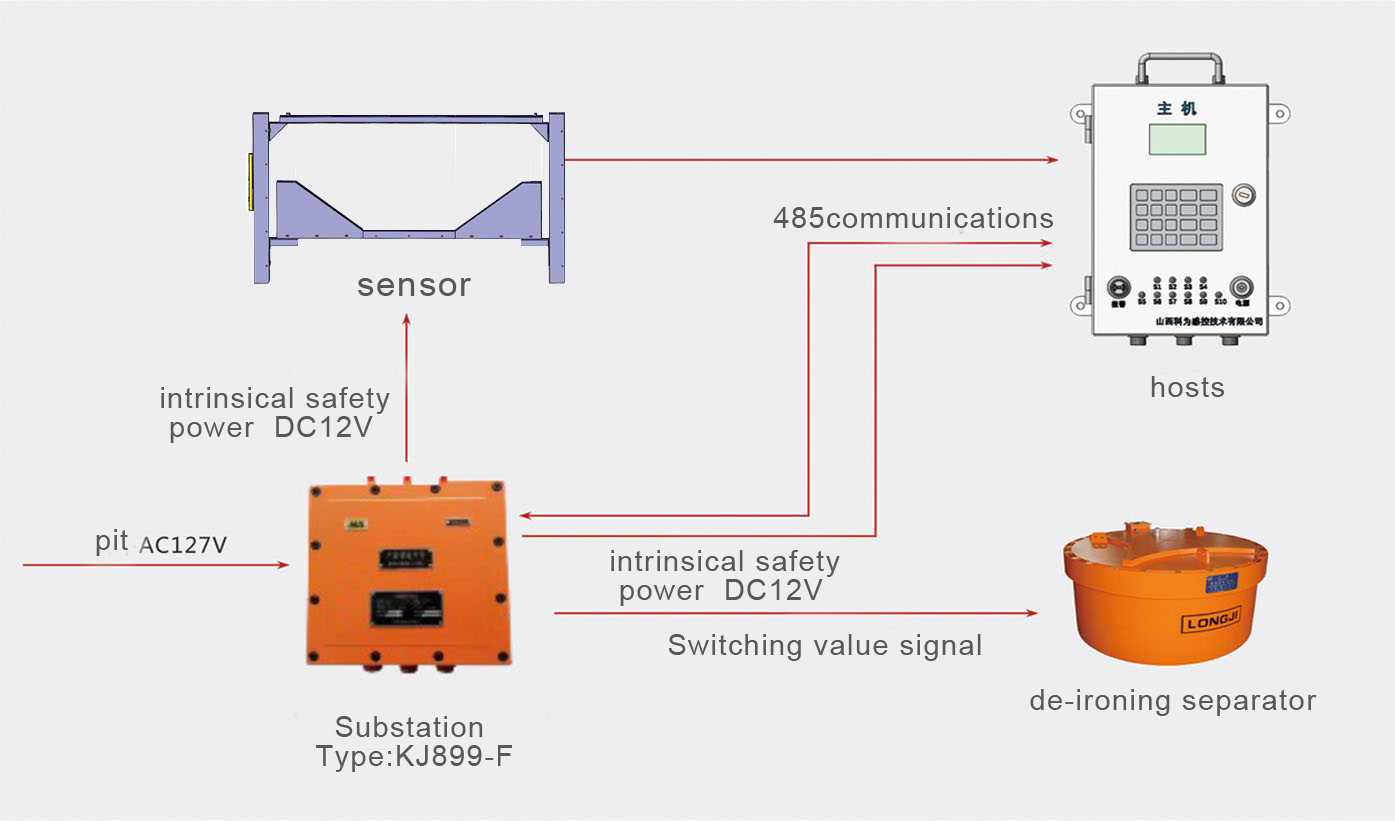

System Composition

Technical Specification

1 Applicable conveyor belt width:800mm-2000mm,can also be customized.

2 Transportation on behalf of running speed:0.2~10m/s

3 Working voltage:AC127V/660V

4 Ambient temperature:-20℃~60℃

5 Humidity:≤96%RH

6 Host explosion-proof form: intrinsically safe

7 Explosion-proof power supply: explosion-proof and intrinsically safe

8 Optimal sensitivity:¢15mmX15mm

9 Detection accuracy:≥99%

10 Maximum detection distance:500mm

11 Output relay capacity:250V/3A

12 Protection level:IP54

13 Machine power:80W

14 Machine quality:50Kg

15 Communication method: CAN or RS485

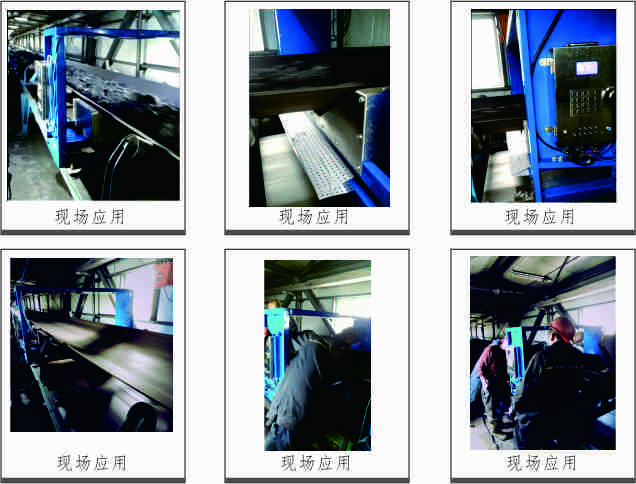

Applications

| 上一个:KJ898 | |

| 下一个:KWTC00 |

SHANXI KEWEI INDUCTIVE

CONTROL CO.,LTD

Add:DongMin Technology Building,

Taiyuan University of

Technology, Shanxi

Tel:86 351 3292666

Fax:86 351 6580268

E-mail:sxkwgk@126.com

Home | About Us | Product | Our Service | Contact us

Tel:86 351 3292666 E-mail:sxkwgk@126.com Add:DongMin Technology Building, Taiyuan University of Technology, Shanxi

Copyright: SHANXI KEWEI INDUCTIVE CONTROL CO.,LTD Technical support:Taiyuan University of Technology