Product overview

Rim flaw detection device (Model RI-I) is used for the detection of rim defects of various types of CRH EMUs as well as the rail traffic wheelsets of ordinary vehicles, locomotives, subways and the like. It is one of the core equipment for maintenance and safety maintenance. Magnetic flux balance detection technology, while testing the same round of two wheels; equipment is simple to operate. Without dismantling any accessories, complete the entire series of vehicle wheel flaw detection, radial defect detection sensitivity, deep exploration depth, rapid, efficient flaw detection and automatic analysis of defect types and degree of injury. Reached the international advanced level.

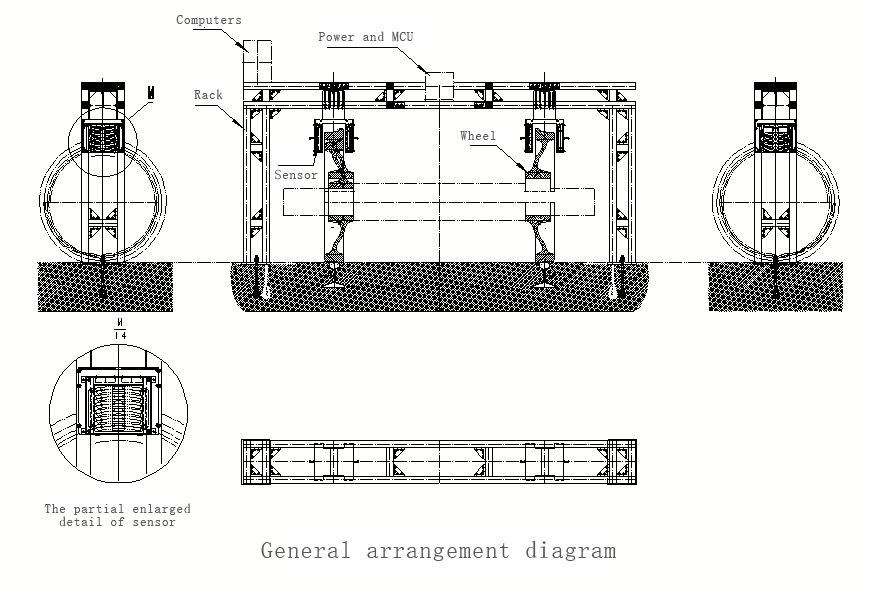

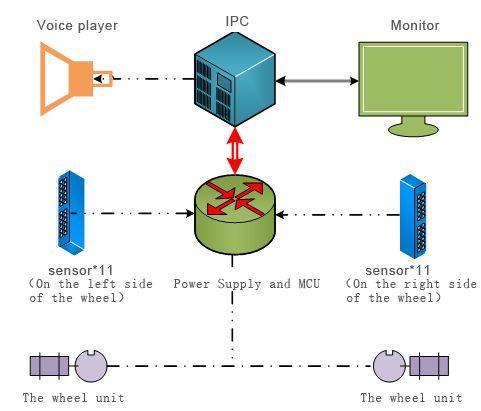

System Diagram

1 Flaw detection sensor:

Two sets of testing sensor group with a total of 22 testing sensors, full coverage without dead ends of a wheel on the two wheels rims, flange defects simultaneously detected. Detected defects into analog signals, the signal is sent to the master control unit.

2 Power and main control unit:

By the power module, data processing module and communication module. Power supply for 22 testing sensors, data processing module, communication module to provide power. Data processing module is mainly completed the sensor signal analog-digital conversion and processing package transmitted to the communication module; communication module through the bus to send data to the industrial control computer.

3 Voice player:

Through the voice, complete the operation prompts, damage alarm and other functions.

4 Industrial Computer:

Complete data processing, data storage, damage analysis, generate reports, alarms, data indexing and other functions.

5 Touch the monitor:

Real-time dynamic display and complete human-computer interaction of the inspection process, system settings, data query and other operations.

6 Rotor:

Includes jacking unit and wheel unit. The lifting unit is used for lifting the wheel to be tested, and the wheel unit is used for rotating the wheel, so as to simultaneously lift and drive the two wheels to rotate.

Functions

The flaw detection system can realize the automatic detection of the train wheels, and simultaneously detect the rims, spokes, rims and the rims of the two wheels at the transition region between the rims and the spokes, and can detect the circumferential rifle crack, the radial crack, the radial direction of the rims Cracks on the whole wheel rims with clear targeted, so that the wheel of the major hazards of defects can not hide, to ensure traffic safety.

System Characteristics

1 After the first wheel reaches the testing station, the turntable is started to lift the wheelset and rotate in situ. The sensor detects the damage of the entire rim during the rotation of the wheelset.

2 Rounds of rotation about 6 laps to complete the test, this time the computer can automatically generate test reports, significantly improve the testing efficiency.

3 Achieve dynamic detection of wheel rim surface and internal defects, the software automatically analyze the type of defect and the degree of injury and generate test reports.

4 Complete the wheel within a day test results summarized, generate test reports.

5 Complete data services: for the user to establish a comprehensive database and backup database.

Technical SQpecification

1 Sensitivity (not less than the following ultrasonic measurement standards):

① internal Injury: 10mm from the surface of the depth of the diameter of 2mm flat-bottomed hole equivalent; from the surface of the depth of 30mm diameter of 3mm flat-bottomed hole equivalent.

② external Damage: local point defects: Ø2mm hole equivalent size 220V.

③ Crack: 5mm × 1mm notch equivalent size

2 Radial crack detection accuracy of 100%, other injury detection accuracy ≧ 99.5%.

3 False positive rate: less than 0.5%.

4 Detection repetition rate: 99%.

5 Scope of application: Suitable for the wheel rim test of various wheel pairs currently in use.

6 Sensor and rim allow relative linear velocity: 1.0-10m / s.

7 Sensor and rim allow clearance: 5 ~ 15mm.

8 Equipment working environment:

① system supply voltage:127/220VAC

② machine rated power (excluding wheel):150W

③ The whole curb weight (excluding wheel):120Kg

④ system temperature:-25℃-+60℃

⑤ sensor working voltage:12VDC

⑥ sensor working humidity:≤95%RH

⑦ computer operating humidity:≤50% RH

9 Reserved RJ45 / RS485 interface.

Test Cases

| 上一个:KWTC00 | |

| 下一个:none |

SHANXI KEWEI INDUCTIVE

CONTROL CO.,LTD

Add:DongMin Technology Building,

Taiyuan University of

Technology, Shanxi

Tel:86 351 3292666

Fax:86 351 6580268

E-mail:sxkwgk@126.com

Home | About Us | Product | Our Service | Contact us

Tel:86 351 3292666 E-mail:sxkwgk@126.com Add:DongMin Technology Building, Taiyuan University of Technology, Shanxi

Copyright: SHANXI KEWEI INDUCTIVE CONTROL CO.,LTD Technical support:Taiyuan University of Technology