1 steel wire rope magnetic flaw detection technology listed in the directory of "key technologies for prevention and control of major accidents in state safety production" in China.

2 steel wire rope magnetic flaw detection technology that won the "China machinery industry science and technology award".

3 Magnetic balance detection technology does not require deep magnetizing wire rope and is simple in structure¡£

4 broken wire detection sensitivity£¨0.5% of the cross-sectional area of the wire rope£©¡£

5 It can overcome the influence of steel wire rope jitter on the measurement and can measure no matter internal broken wire or the external broken wire.

Product Overview

Mine hoist is a large mechanical equipment. The motor drives the mechanical equipment to drive the wire rope so as to lift the container up and down in the wellbore. According to the connecting form of wire rope on the drum, it can be divided into winding hoist and friction hoist. According to the lifting rope, it can be divided into two ropes, four ropes and six rope hoist.This product uses the patented "magnetic balance" detection technology to realize the comprehensive safety monitoring of the steel overhead traveling rocket device. Real-time online monitoring of defects such as broken wires, rust, abrasion, elasticity reduction and connector tangling can prevent broken ropes and save the cost of inspection and maintenance and rope changing.

1 Make the steel wire rope under a fully controlled and safe condition in operation process.

2 Combining the production process and inspection process into one, which reduces one process, increases operation time and raise the rate of equipment utilization.

3 Reducing the idle energy consumption of equipment specially for testing wirerope.

4 Making the service life of wire rope more effective and proper, saving wire rope replacing time and reduce the cost of wire rope.

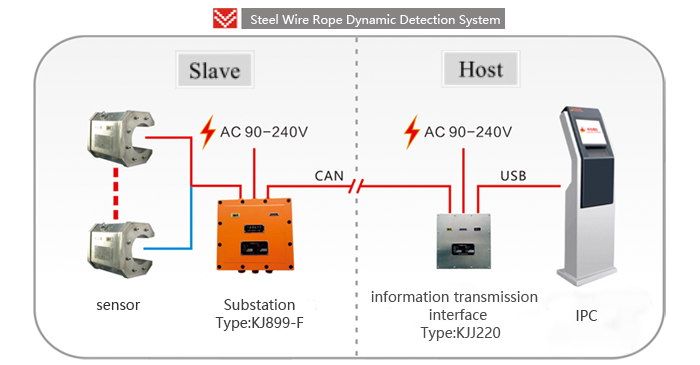

System Composition

1 Sensor :Integrating Non-Contact Speed Sensor and single chip microcomputer,

the sensor detects the flaw of the wirerope and transforms it into an analog signal .The single chip microcomputer achieves the conversion from analog to digital and the signal processing ,then transforms the useful signal into the CAN bus signal .

2 Substation: (type of protection £ºflameproof enclosure & intrinsic safety )Be composed of the Intrinsically Safe Power¡¢the servo single chip microcomputer and the Data acquisition and communication module.The Intrinsically Safe Power(12V/2A) supplies power to sensors group and single chip microcomputer separately.According to host computer’s order , the servo single chip microcomputer opens and closes main supply power , or stops steel wire rope running.The Data acquisition and communication module mainly receives the signal from sensor groups , then processes and packages for transmitting to the host computer.

3 Transmission interface: As a safety barrier ,it is composed of the Intrinsically

Safe Power and the Communication data conversion interface.The former supplies power to the latter. Communication data conversion interface transforms the CAN

signal into the USB signal , which is transmited to computer.

4 Industrial computer stations on the host: from the special cabinets, industrial computers, special wire rope data processing software, printers, SMS notification module. Role for the collection and processing of data, display graphics, store data, analyze and determine the type of defect, generate test reports, print reports and text messages to inform customers.

Product Overview

Our company is committed to continuously exceed and innovate, in addition to the following products have the following basic functions, but also based on and customer requirements to achieve more personalized features.

1 The principle of advanced£º

Based on the principle of magnetic flux balance magnetic metal material defect detection and the sensor, the influence of wire rope jitter on the measurement can be completely eliminated. The external wire breakage and the internal wire breakage can be detected as well and the movement direction of the wire rope can be measured.

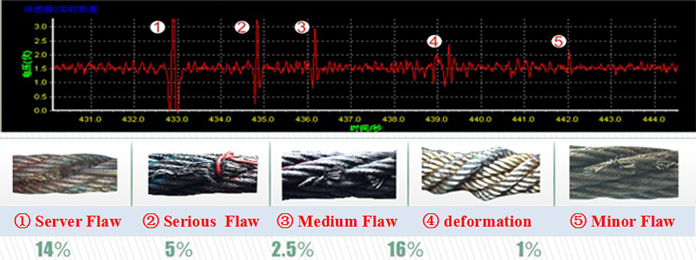

2 Online monitoring, accurate positioning£º

To achieve a broken wire rope, deformation, wear and tear. Corrosion, loose stock, jumping wire and other defects of the type of real online monitoring, and accurate positioning.

3 Precise sensing£º

Can accurately measure the internal broken wire and the valley at the broken wire (broken wire in the valley may indicate damage inside the wire rope), broken wire detection sensitivity of 0.5% (LF) wire rope cross-sectional area, LMA detection sensitivity of 1%. It can calculate the cross-sectional area of the broken wire in one lay length and compare with the total cross-sectional area of the wire.

4 Non-contact measurement:

Speed sensors, testing sensors are non-contact wire rope sensor, safe and efficient.

5 Audible alarm£º

When found in a lay length of two valley broken wire, the system can automatically alarm to meet the GB / T 5972-2009 crane wire rope maintenance, installation, maintenance, inspection and scrap standard 3.5.2 --- when in a pitch Within two or more of the valley found broken wire, wire rope should be considered scrapped.

6 The degree of damage to the wire rope Comprehensive Assessment Function£º

On the wire rope partial damage degree of individual assessment, a comprehensive assessment of the remaining carrying capacity.

7 Defect intelligent search function£º

All detected defects can be found by computer software control. After setting the search target, the system automatically stops the rope when it passes the sensor. The user can find the defect within 100mm from the exit of the sensor to facilitate further inspection or repair.

8 Automatic notification£º

Alarm information, test reports can be printed and SMS notification function

9 Remote shutdown power£º

Remote operation, the software is running, the system automatically power-on, the software stops running, the system automatically power down.

10 Data will look, photo comparison£º

Realize historical data review, take pictures, contrast function, changes in wire rope operating conditions more intuitive.

11 One interface, multiple objects£º

Software interface can simultaneously show multiple wire rope detection curve, rope more, at a glance.

12 Automatic shutdown£º

The system can be based on user needs, serious damage to the wire rope, cut off the motor power, so that wire rope stop running, to ensure production safety.

13 Software self-test function£º

When the system sensor, microcontroller, interface or transmission cable and other equipment failure, automatically prompts the fault information.

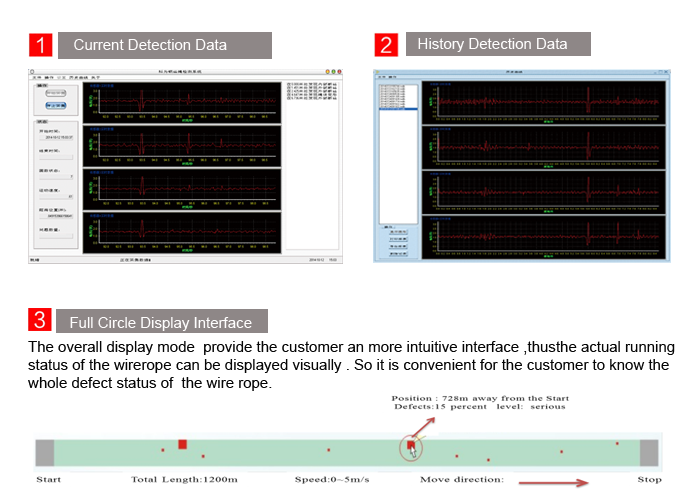

14 Whole circle shows£º

User-friendly operation of the overall state of the rope rigorous control.

15 Internet of Things£º

Branch can help users to remotely monitor the running status of the rope, and the monitoring report in a humane manner to the user feedback.

16 Waterproof, dustproof, shockproof£º

Sensor with stainless steel seamless shell design, waterproof, dustproof, shockproof.

17 automatically generate test reports£º

The report covers key areas of interest to users such as defects, percentage of defects, percentage reduction in wire rope strength, and remaining useful life.

18 system software support WindowsXP and Windows7 and so on.

Technology lnnovation

1 Adopt Canadian technology, patented product.

2 Sensor technology uses the invention patent - flux balance measurement principle. The measurement sensitivity is very high, and can overcome the influence of wire rope jitter on the measurement accuracy. The wire rope internal and external broken wires can be effectively detected.

3 The use of strong anti-interference circuits and related measures can effectively overcome various radio and magnetic interference, power pollution and mechanical vibration effects.

4 Sensitivity of the sensor: the sensitivity of the broken wire is 0.5% of the cross-sectional area of the wire rope.

5 To achieve a real DC amplifier, the sensor output signal size and wire rope speed has nothing to do.

6 According to measure the direction of rope movement, that is, rope is normal or reverse.

7 Non-contact measurement of wire rope speed sensing technology.

8 Multi-sensor unit detection, to solve the problem of blind measurement of wire rope.

9 Innovative Internet of Things concept application. My company through the Internet of things for the establishment of customer service center to achieve remote data operations (via the Internet or phone card), remote user services: daily timing for the user to detect damage to the wire rope and testing equipment operating conditions, and a detailed test report SMS, e-mail or fax to the user.

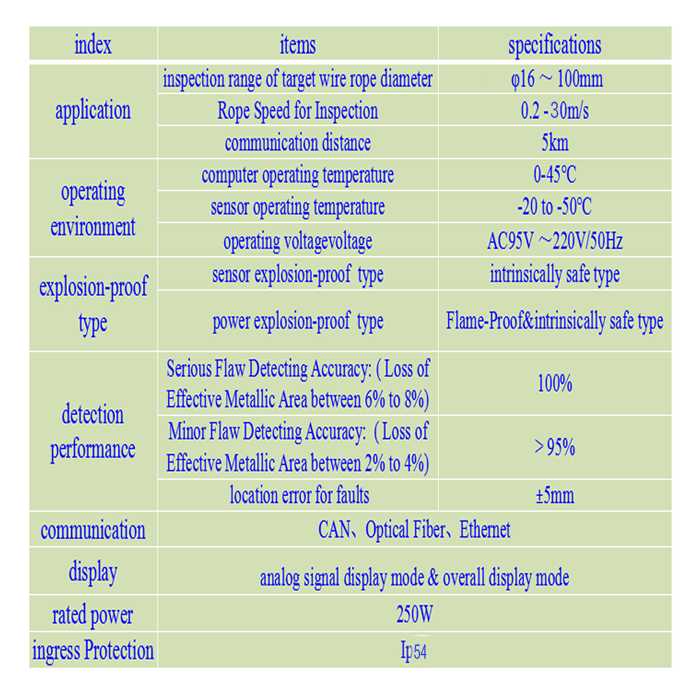

Technical Specification

Software Lnterface

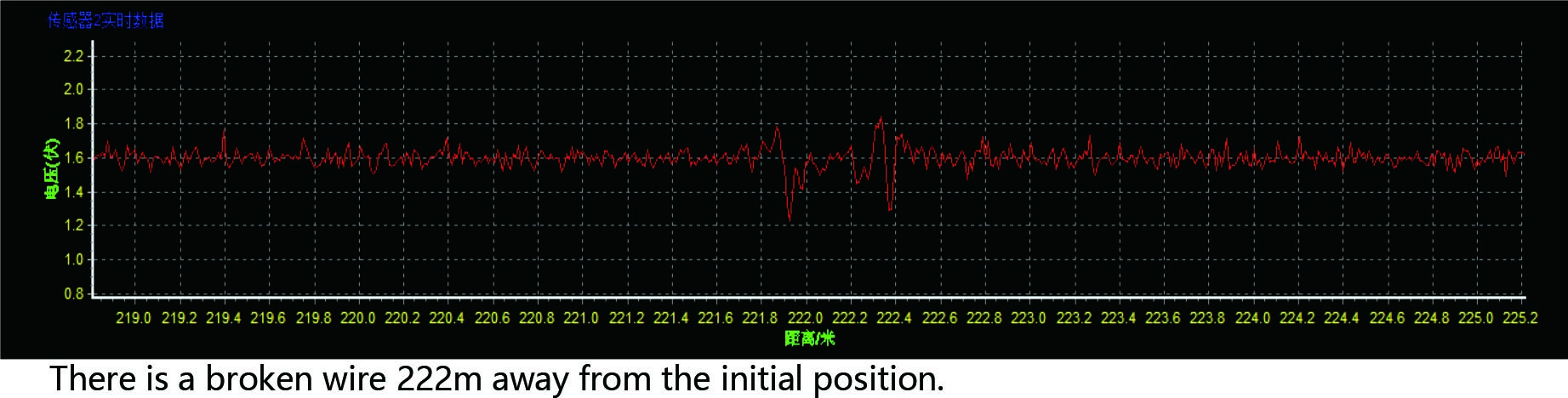

Measurement Graph Description

Applications

| ÉÏÒ»¸ö£ºKJ899(hoist) | |

| ÏÂÒ»¸ö£ºKJ965 |

SHANXI KEWEI INDUCTIVE

CONTROL CO.,LTD

Add£ºDongMin Technology Building,

Taiyuan University of

Technology, Shanxi

Tel£º86 351 3292666

Fax£º86 351 6580268

E-mail£ºsxkwgk@126.com

Home | About Us | Product | Our Service | Contact us

Tel£º86 351 3292666 E-mail£ºsxkwgk@126.com Add£ºDongMin Technology Building, Taiyuan University of Technology, Shanxi

Copyright£º SHANXI KEWEI INDUCTIVE CONTROL CO.,LTD Technical support£ºTaiyuan University of Technology